Leather cutting: the “all inclusive” concept – no more optional features, no more extra payment.

We solve all the problems of leather cutting process, offering the cost-effective cutting system, completed by the best software and automatic technology.

The “all inclusive” concept – no more optional features, no more extra payment

Before entering the leather cutting market, Kuris has accumulated a valuable experience on the Turkish market by selling CAD for textiles. Our success on this market is based on the simple and honest selling strategy: any useful feature of the system must be included as standard. No extra money for extra options. All inclusive. No matter what kind of cutter you buy, you will get the full software package with all features included, with no extra charge. The “all inclusive” technology package means that even for the cheapest cutting systems the customer will benefit from all high-end technologies like automatic leather digitizing and automatic nesting, bar-code labeling system, printed reports, video-projection system, etc.

Cutting leather by using the Kuris automatic system is a very simple STEP by STEP process:

1. Production plan

Styles and patterns import and conversion, production quantity management, work distribution on one or several cut stations.

2. Leather scan

Leather contour automatic detection, Quality zone declaration on 5 levels using video-projection, bar-code label printing, leather purchase report.

3. Automatic nest

Automatic and interactive nesting directly on leather, automatic quality zone matching, easy to use wireless mouse and keyboard.

4. Cut

Automatic cutting and marking using a variety of tools: oscilating knife, round knife, laser, punch with different diameters, drills, pens.

5. Collect

Interactive and efficient piece collecting procedure after cut, using video-projection. Different collecting methods depending on production type.

6. Reports

Comprehensive reports for leather stock, cut efficiency, consumptions, minimarkers, production quantity reports.

System configuration – from 10 to 1000 hides a day, we have the solution.

The system can be configured for any production volume from very small workshops where just few hides are cut every day up to large factories with hundreds of hides to be cut daily.

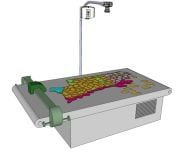

BASIC SYSTEM: ALL ON CUTTER

Compact configuration that offers all features of a large system: leather scan, automatic nesting, collect and reports. All these operations are performed directly on cutter table, in a very fast and efficient process. This cutter is suitable for workshops and small factories, up to 50 hides a day.

MEDIUM SYSTEM: IN LINE

To increase the productivity, the process is divided into 3 steps:

- leather scan and nesting;

- cutting;

- collecting.

But these three steps are performed directly on the machine: a conveyor belt is moving the leather from one stage to another, in a continuous and efficient workflow. This configuration is recommended for medium factories, that cut up to 200 hides a day.

DATA SHEET

Download