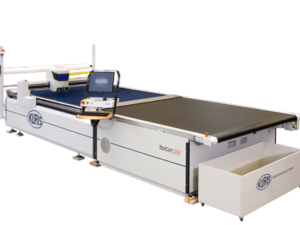

Automatic mat cutting, suitable for technical textiles and special materials such as aramid, carbon and glass fibers, prepregs and insulation materials, sports and leisure products, for samples and series production in the clothing, furniture and automotive industries and many other industrial sectors.

DESCRIPTION

In many areas of the manufacturing economy, the needs of an increasingly global market are leading to improvements in production processes. In many cases, this means moving tasks that were previously done manually to automated machines. This need requires technology high enough to increase productivity, but at the same time simple enough to pave the way for beginners to use automatic cutting.

Kuris has implemented this requirement with the TexCut 25, 30, 45, 60, 70, 80 machines.

ADVANTAGES

• Fiber belt with a cutting window of 2.2 m, 3.5 m or 4.5 m allows optimal adjustment of the size of the workpieces and files to be cut

• Excellent cutting quality, even with difficult cuts, contours and hard materials thanks to the automatic deflection with knife compensation (option: Smart Knife)

• High cutting speed ensures highly effective cutting performance even for single layers

• Low energy consumption thanks to the suction unit, the power of the empty and optimally controlled (option)

• Easy maintenance thanks to standardized components

• Quick and easy changing of the blade and cutting head thanks to the patented service position

• Automatic parallelism check – no manual layer pack alignment.

• Automatic reliability check – prevents incorrect cuts in case of wrong operations

OPTIONS

• The system can be moved on several spread tables, to collect layers of fabrics.

• Pattern repeat and stripes

• Break control with an electric knife

• Drawing device

• Drill for holes with a diameter of up to 20 mm

• Vacuum device (Resealer)

• Milling device

• Smart knife

TECHNICAL SPECIFICATIONS

• Cutting heights: Compressed up to 80 mm

• Maximum cutting speed: 45 m/min

• Positioning speed: 60 m/min

• Working widths: 1.90 / 2.20 / 2.40 m (others on request)

• Total width of the cutting frame: 2.25 / 2.55 / 2.75 m

• Total length of the cutting frame: 3.20 / 4.50 / 5.50 m

• Effective cutting length: 2.20 / 3.50 / 4.50 m

• Length of the clearing surface: 2.00 / 2.50 / 3.30 / 4.30 m

• Total width of the cleaning belt: 2.10 / 2.40 / 2.60 m

• Total length of the cutting system: 5.20 / 5.70 / 7.80 / 9.80 m

• Weight of cutting system: approx. 3600 – 3900 kg

• Weight of the vacuum system: approx. 600-800 kg

DIMENSIONS OF KNIVES

• 1.2 x 6.0 mm

• 2.0 x 6.0 mm

• 2.0 x 7.0 mm

• 2.5 x 8.0 mm

• 3.0 x 9.0 mm

ELECTRICAL CONNECTION

• Operating voltage: 230 / 400 V, H3, 400 V, 3, 50, 50 V, 50, 50.00 V, 3,000,000 V.

: 4kW

• Economical vacuum system: 22/30 kW

• Compressed air (5-6 bar): 10 l/min

• (per platform): 230 l/min (temporary)

• Noise level: 57 – 74 dB(A)

DATA SHEET

Download