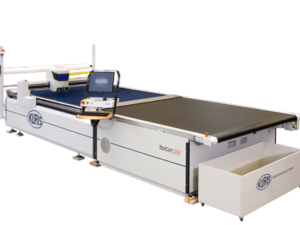

DESCRIPTION

Compact, fast and reliable! The TEXCUT 3001 single-sheet cutting system is part of the fourth generation of proven cutting systems, which are fully optimized and designed to meet your needs with maximum productivity and production quality.

The main features of these systems are cutting heads with a programmable Z axis and equipped with a Multiflex tool.

Adaptive tooling technology can be individually and precisely adapted to the respective material. This means that optimal cutting conditions are always achieved. In addition to the extremely short immersion time, this system also impresses with its high travel and cutting speeds. With the tool change system, set-up times are also significantly reduced, as only a few adjustment steps are required.

visitexLOC by KURIS powered by digMAR

The visitexLOC image processing system was specially developed for Kuris textile and carpet cutting machines and is used to automatically determine the cutting coordinates. Depending on the needs, the materials to be cut are scanned in 2D or 3D using the camera. The cutting coordinates calculated in this way are then transferred to the cutting system for further processing.

In addition to the ability to enlarge or reduce the scanned shapes as desired, it is also possible to round the corners to your liking. Various calculation modules that can be adapted to customer requirements help the operator to determine the optimal cutting coordinates. Predefined standard calculation modules help the operator to determine the optimal cutting coordinates:

• Free form

• Rectangle

• Square

• Circle

• Specific: This allows you to create any number of customer-specific and freely defined vector calculation modules that can be applied to found shapes within a scan.nen.

• Default: use predefined shapes in file. Supported file types are dxf, pcx, bmp, tif, png, jpg.

• Tiles: places a freely defined sequence of subshapes on the found shape.

• Grid: places a freely defined grid on the found shape.

RECORDS – RECOGNIZE – CUT

The fabrics/carpets are recorded with the integrated camera system. Cameras enable quick recording and immediate reproduction of the scanned image.

The software processes and filters the captured images so that the mesh is directly generated for cropping. The cut files are transferred from the scanning software (visitexLOC) directly to the HMI, without additional commands from the operator. No CAD files required.

Developed for the toughest conditions. Cutting head with a high number of blows (14,000) and a special knife with 2 blades with a cutting height of 15 mm.

The modular cutter can also be equipped for the following applications:

milling, drilling/marking, with oscillating knife or motorized circular knife.

ADVANTAGES

• Speed

• Precision

• Quick tool change

• Quick setup

• Mobile control terminal

• Excellent cutting quality

• Long life

• Fast maintenance

• Easy to use

OPTIONS

• Basic head

• Carpet cutting head

• Plotting device

• Drilling device

• Milling device

• Water circular knife

• Oscillating Blade 1 shot, 2 shots, 5 shots

• Zone vacuum

• Printhead

• Vacuum pump of 7.5 or 11 kW

TECHNICAL SPECIFICATIONS

• Maximum cutting height: 40 mm (depending on the tool)

• Maximum cutting speed: 70 m/min

• Maximum positioning speed: 100 m/min

• Maximum acceleration: 7 m/s²

• Nominal working widths: 1.75 / 2.10 / 2.75 / 3.25 / 4.05 m

• Table widths: 2.10 / 2.50 / 3.10 / 3.60 / 4.60 m

• Nominal working lengths: 2.30 / 3.50 / 4.50 m

• Total lengths: 3.80 / 5.00 / 6.20

• The cutting system 1950/ 2300 / 3800 kg

• Working height: ab 0.85m

• Operating voltage: 400V, 50/60Hz

ELECTRICAL CONNECTION

• Control/drives: 4kW

• Vacuum unit: 7.5 kW / 11 kW

• Average consumption: 8 kW

• Fuse: 35 A (5×6 mm²)

• Protection class: Class 1

• Compressed air (5-6 bar): 10 l/min

DATA SHEET

Download