Loading equipment

Loading equipment :

For ergonomics at the workplace and automation, a loading device is necessary for loading our spreading machines. Whether cradle, bar or for automatic grabbing from a paternoster, we have various loading devices on offer for our various machine types and applications.

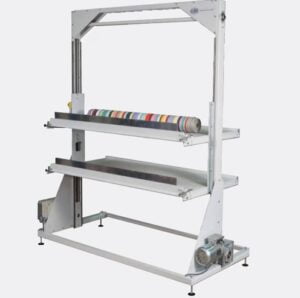

C350

For cradle-spreading machine

By motor and chain driven lifting device with two platforms for lifting, storing and loading of fabric balls up to a diameter of max. 40 cm. Particularly suitable for loading and unloading of a cradle-spreading machine which operates without rods.

The motor of the loading device is controlled and moved by a frequency converter and a worm gear. Its holding position is fixed by a magnetic brake.

The C350 is equipped with two loading platforms, which can be moved steplessly upwards and downwards by using the manual control. The fabric rolls can be rolled directly from the forklift or a transport trolley onto the platform.

Running noise: 65 dB (A) measured at a distance of 1m at running idle

Machine model according to EC directive

TECHNICAL SPECIFICATIONS:

Lifting force: max. 350 kg

Machine length: approx. 1150 mm

Machine height: approx. 2480 mm

Total width: approx. 2440 mm

Max. opening: 2020 mm

Max. ball diameter: 400 mm

Max. lifting height: max. 1200 mm

Min. lifting height: min. 160 mm

Rated power supply:

Engine power: 1.5 kW

Operating voltage: 32 V, 50/60 Hz

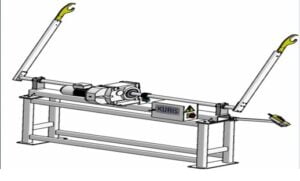

Quick-Lift

Meant for spreading machines with rods

The Quick-Lift by Kuris loads and unloads the spreading machine with roll material. Two rotary arms lift the roll material, for example from the floor into the machine.

In combination with the thread-in process of a KURIS spreading machine, the loading and unloading is particularly simple and very efficient. After spreading, the unloading of the fabric roll will be executed by the grippers or hooks without any hand grips on the Quick-Lift.

The Quick-Lift is mounted on the table or a special rack and can lift the fabric rolls from the floor into the spreading machine. Two speeds allow for a quick pickup as well as a gentle loading of the fabric roll. The Quick-Lift can also be installed on a carrier, so that two side-by-side spreading machines can be operated by only one loading device. Subsequent mounting on an already existing line of the spreading machine is possible.

The Quick-Lift unburdens the operator considerably. The Quick-Lift makes it easier for the spreading machine to be equipped with a fabric bar and even more economical.

It is available in various mounting versions:

1.mounting on the table

2.installation behind the table

3.as a mobile version

4.in combination with a carrier

Running noise: 65 dB (A) measured at a distance of 1m at running idle

Machine model according to EC directive

TECHNICAL SPECIFICATIONS:

Roll weight: max. 120 kg

Material roll diameter: max. 1000 m

Overall height: 2280 mm

Working width: 1680 mm to 2280 mm

Rated power supply:

Power: 2.2 kW

Operating voltage: 230/400 V, 50 Hz

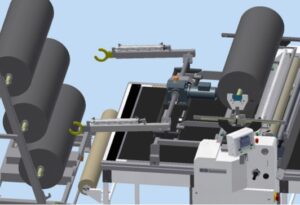

Speed-Lift

Integrated into a spreading machine with bar

The rolled goods can be picked up directly from the table level by the Speed-Lift and inserted into the winding-up bar of the Shuttle / A23. The speed-lift is controlled by the control unit of the spreading machine.

ADVANTAGES:

1.saves off-peak

2.relieves your employees

3.ergonomic application

4.Running noise: 65 dB (A) measured at a distance of 1m at running idle

5.Machine model according to EC directive

TECHNICAL SPECIFICATIONS:

Roll weight: max. 60 kg

Material roll diameter: max. 600 m

Working width: 1680 mm to 2280 mm

Rated power supply:

Power: 1 kW

Operating voltage: 230 V, 50/60 Hz